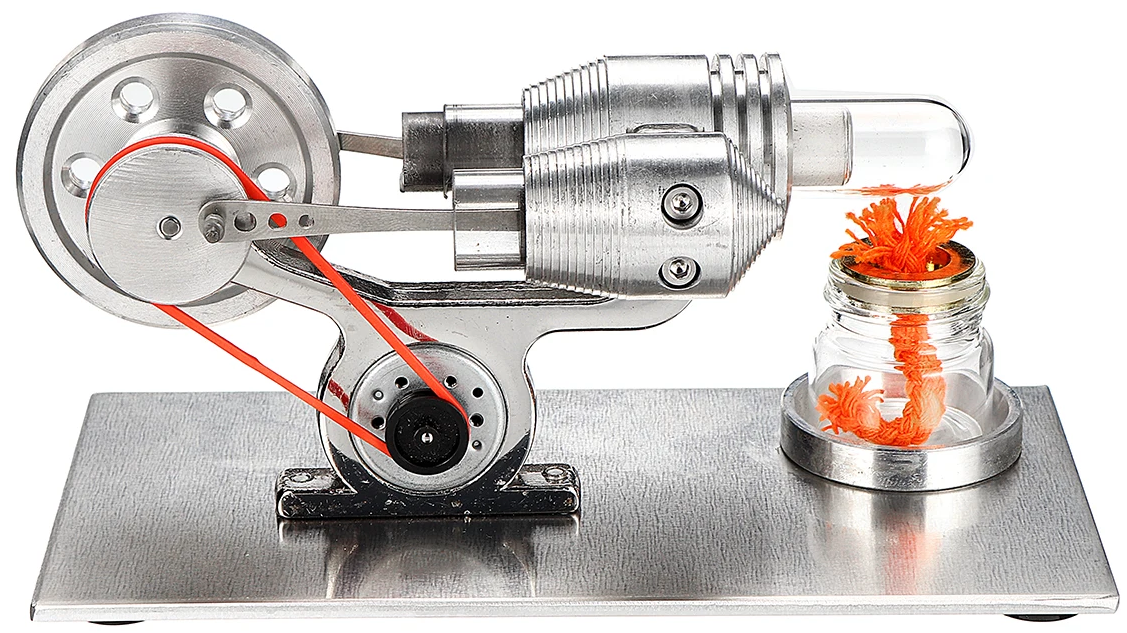

Stirling Engine

Mechanical device that converts thermal energy into mechanical energy by compressing and expanding a fixed quantity of gas in a chamber. The gamma Stirling engine has a power piston and a displacer in separate chambers and because of that it’s easier to manufacturer than beta Sterling engine. The alpha engine has two power pistons (in separate chambers) and because of that has a better power/weight ratio than beta or gamma.

Components:

- Hot chamber: Chamber containing gas which is subject to continuous heating.

- Cold chamber: Chamber containing gas which cools down by dissipation of heat.

- Connecting bridge: Physical connection between hot and cold chamber allowing the gas to circulate freely between both.

- Power piston (2x in alpha stirling engine): tightly sealed piston that moves back and forth by the action of the expanding and contracting gas in the chamber. (Note: the alpha engine has one piston in each chamber.)

- Displacer (only in beta and alpha models): a loose piston that moves back and forth allowing the gas in the chamber to flow from one side of the displacer to the other making the cooling process more efficient when compared to alpha engine.

- Fly wheel: This element spins and gains momentum which is key to maintain the motion and helps the engine cycling through the four main stages.

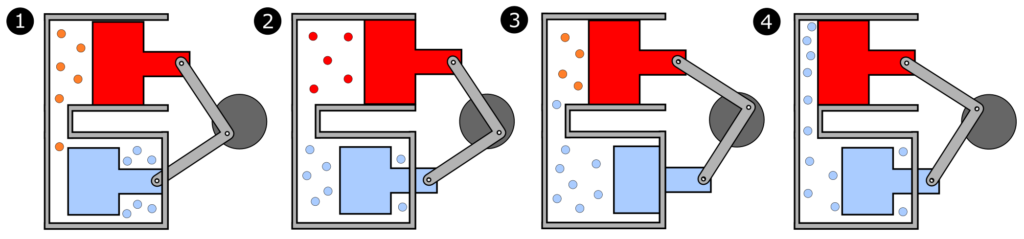

Key feature: The movement of the piston and displacer (the 2nd piston in case of alpha engine) is out of phase by 90 degrees.

Working Principle:

One chamber is continuously heating, whereas the other is always cooling the gas.

- The gas on the heated side (in red) expands and pushes the piston out.

- The gas reaches maximum volume.

- The fly wheel keeps moving the system and starts pushing the hot piston back down and the displacer (in blue) in the cold chamber further out. The gas moves across the displacer bringing the cold gas into the hot chamber.

- As it cools down it contracts and brings the hot piston further inwards. The gas reaches its minimum volume. The momentum of the fly wheel keeps the system in motion pushing the displacer in. The process repeats from step 1.

Instructions:

- Light the cotton thread embedded in alcohol (95%).

- Start spinning the fly wheel manually to overcome initial inertia.

- From that moment onward the engine will continue working as long as the heat source is present.

Links:

STEM Stainless Mini Hot Air Stirling Engine Motor Model – Banggood Toy&Hobbies

Stirling Engines – How They Work

Alpha type Stirling Engine – Renewable Energy – Stirling Engine